#Cnc simulator pro italiano software#

Thanks to this, the iterations of CNC programming become less time consuming, and comparing to other CAD/CAM software the CNC programming workflow itself becomes intuitive and clear. Para fresar cualquier parte, en cualquier mquina CNC, para cualquier sector.

#Cnc simulator pro italiano how to#

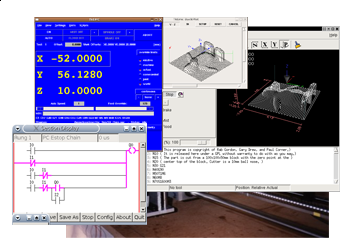

Using the result, the user can easily decide how to correct the parameters without switching to simulation or postprocessing. Immediately after the toolpath is calculated, SprutCAM performs the simulation in the background and shows the new state of the workpiece to the user in the same window. It can drive milling machines, lathes, 3d printers, laser cutters, plasma cutters, robot arms, hexapods. This means that the CNC machine is 100% able to execute the generated program. LinuxCNC: an open source CNC machine controller.

The result of the calculation is not just the Cartesian points in abstract space it’s the actual positions of the machine axes required to reach these points. Kinematics and rest material consideration on every stepĪll the limitations of the machine model kinematics and the actual rest material that remains after previous operations and the fixture(s) geometry are used to calculate the toolpath. After that it’s easy to estimate the reachability of the surfaces when picking them for the machining. Before starting the programming, the user puts the models of the part and fixtures inside the virtual machine. The Tebis CNC Simulator lets you fully plan, program and check your NC machining operations with all components in the Tebis NC programming environment.Prerequisite: All machines, tools, units and clamping devices are stored with components on a one-to-one basis as digital twins in the virtual manufacturing environment. SprutCAM is a CAD/CAM software that takes into account the CNC machine model during the toolpath calculation. if you want a legit software, you can prefer davinci resolve.

0 kommentar(er)

0 kommentar(er)